E series, using the innovative human-computer interactive control system and 5-inch colorful resistive touch screen, integrating functions of Internet of Things (IOT) and cloud platform.

E series, using the innovative human-computer interactive control system and 5-inch colorful resistive touch screen, integrating functions of Internet of Things (IOT) and cloud platform, embedding new purification cartridges with patented structure, rigorous double RO system, advanced EDI module and DI ion-exchange cartridges with larger capacity, equipping with built-in 1.8-liter pressure water tank, can meet your critical and professional application requirements of lab pure water.

System output ranges from 10 to 60 liters/h. It can simultaneously produce ultrapure water (18.2MΩ.cm), high pure water (>17.5MΩ.cm) or pure water[3]. The quality of pure water fully meets or exceeds the requirements of water quality standard specified by ASTM D1193-06, GB/T 11446.1-2013, GB/T 33087-2016, GB/T 6682-2008, CP, EP, USP, JP, CAP, CLSI, etc.

[1] The double RO system is only used for EUS/EDS/ERS series products.

[2] EDI module is only used for EUE/EDE series products.

[3] ED/ERS series products can produce single RO water (ion rejection rate≥98%). EDS/ERS series products can produce double RO water (<5μs/cm).

Laboratory water Application Area:

HPLC,UPLC,LC-MS

ICP-MS,ICP-AES,AAS,GC-MS

MALDI-TOF-MS,IC,TOC analysis

Electrochemical, spectrophotometric determination

Preparation of microbial media and reagents

Cell culture, PCR, IVF

Protein purification, electrophoresis, biochemistry

Proteomics, genomics, immunoassay

Feed water of laboratory instruments, such as: autoclave, bottle washing machine, environmental test chamber, water bath, etc.

There are many models of E series pure water machines, and the differences between different models are mainly reflected in the following aspects:

Different water production: There are a variety of options for water production from 10 liters to 60 liters/hour. For example, the water production of EU-20, ED-20 and other models is 20L/h, EU-40, ED-40, etc. is 40L/h, and EU-60, ED-60, etc. is 60L/h. Users can choose the appropriate model according to the actual water consumption needs.

Different water quality and functional configurations:

Basic types: such as EU-20, EU-40, EU-60, etc., ultrapure water (18.2MΩ.cm) and high-purity water (>17.5MΩ.cm) can be produced simultaneously.

Low organic compound type: models such as EU-20UV, EU-40UV, EU-60UV, etc., have added ultraviolet disinfection (UV) modules on the basis of the basic model, which can destroy bacteria and virus DNA through ultraviolet radiation, inhibit microbial growth, and reduce organic compound content in water. It is suitable for experiments with strict requirements on organic compound content, such as HPLC analysis, etc.

Thermal removal prototype: Models such as EU-20UF, EU-40UF, EU-60UF, etc. are equipped with ultrafiltration (UF) modules, which can effectively remove impurities such as pyrogen in water and produce pure water for thermogen removal prototypes. They are suitable for pyrogen-sensitive scenarios such as cell culture.

Comprehensive types: for example, EU-20UVF, EU-40UVF, EU-60UVF, etc., which have both ultraviolet disinfection and ultrafiltration functions, which can meet a variety of complex experimental needs.

Bacteria and particle removal type: ED-20UT, ED-40UT, ED-60UT and other models belong to the sterilization and particle removal type. On the basis of producing high-purity water and first-class RO pure water, the ability to remove bacteria and particles has been strengthened.

Different applicable scenarios: models with small water production and relatively simple functions, such as ED-20, ED-20UT, etc., may be more suitable for small laboratories or basic experiments that do not require particularly strict water quality; while models with large water production and complete functions, such as EU-60, EU-60UVF, etc., are more suitable for large laboratories, scientific research institutions, or precise instrument analysis with extremely high water quality requirements.

Control System

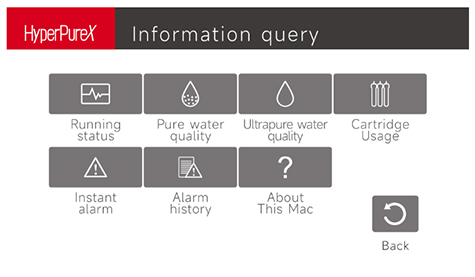

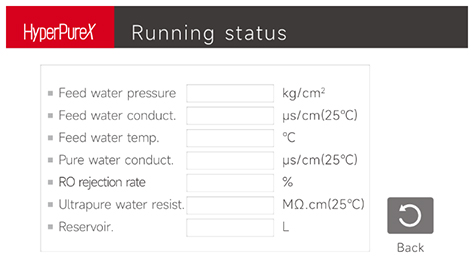

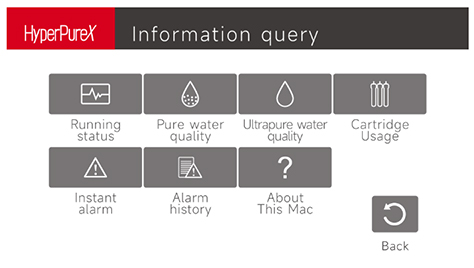

Intelligent human-computer interactive control system

Traceable comprehensive data management

Comprehensive water quality monitoring and alarm

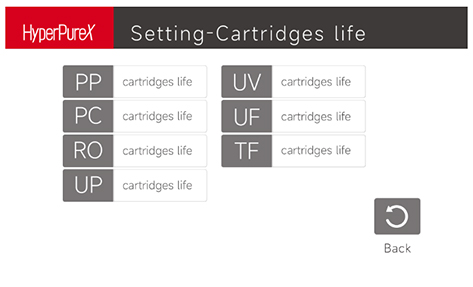

Perfect consumables management

Innovative Internet of Things (IOT) and cloud platform technology

Flexible and diverse water dispensing mode

Professional ultrapure water circulation and disinfection function

Full security protection

System Configuration

Powerful 12-inch pretreated cartridge

Rigorous double RO system

High performance purification cartridge

Professional mini EDI module

Built-in 1.8-liter pressure water tank

Double wavelength UV module

Ultrafiltration module

MF terminal microfilter

UF terminal ultrafilter

Multiple communication interfaces

Specifications

| Name Model | Standard EU-20/40/60 | Low TOC EU-20/40/60UV | Eliminating endotoxin EU-20/40/60UF | Synthesizing EU-20/40/60UVF |

| Production rate | 20 series: 20 L/hour, 40 series: 40 L/hour, 60 series: 60 L/hour | |||

| Dispensing rate | Up to 2 liters/minute | Up to 2 liters/minute | Up to 2 liters/minute | Up to 2 liters/minute |

| Ultrapure water quality | ||||

| Resistivity(25℃) | 18.2 MΩ.cm | 18.2 MΩ.cm | 18.2 MΩ.cm | 18.2 MΩ.cm |

| Conductivity(25℃) | 0.055 μs/cm | 0.055 μs/cm | 0.055 μs/cm | 0.055 μs/cm |

| TOC | 5 ppb | 2 ppb | 5 ppb | 2 ppb |

| Particles | <1 /ml (>0.2μm) | <1 /ml (>0.2μm) | <1 /ml (>0.2μm) | <1 /ml (>0.2μm) |

| Bacteria | <0.01 CFU/ml | <0.01 CFU/ml | <0.01 CFU/ml | <0.01 CFU/ml |

| Endotoxin | N/A | N/A | <0.001 EU/ml | <0.001 EU/ml |

| RNases | N/A | N/A | 1 pg/ml | 1 pg/ml |

| DNases | N/A | N/A | 5 pg/ml | 5 pg/ml |

| Protease | N/A | N/A | 0.15 μg/ml | 0.15 μg/ml |

| DI water quality | ||||

| Resistivity(25℃) | >16 MΩ.cm | >16 MΩ.cm | >16 MΩ.cm | >16 MΩ.cm |

| Conductivity(25℃) | <0.063 μs/cm | <0.063 μs/cm | <0.063 μs/cm | <0.063 μs/cm |

| Particles | N/A | N/A | N/A | N/A |

| Bacteria | N/A | N/A | N/A | N/A |

| RO water quality | ||||

| Ion rejection rate | 98%-99%(with new RO module) | 98%-99%(with new RO module) | 98%-99%(with new RO module) | 98%-99%(with new RO module) |

| Organic rejection rate | >99%(MW>300 Dalton) | >99%(MW>300 Dalton) | >99%(MW>300 Dalton) | >99%(MW>300 Dalton) |

| Particles and bacteria rejection rate | >99% | >99% | >99% | >99% |

| Feed water requirements | ||||

| Water source type | Tap water | Tap water | Tap water | Tap water |

| Pressure | 1-6 bar | 1-6 bar | 1-6 bar | 1-6 bar |

| Temperature | 5-40 ℃ | 5-40 ℃ | 5-40 ℃ | 5-40 ℃ |

| Conductivity | <2000 μs/cm | <2000 μs/cm | <2000 μs/cm | <2000 μs/cm |

| Total hardness(In CaCO3) | <300 ppm | <300 ppm | <300 ppm | <300 ppm |

| TOC | <2000 ppb | <2000 ppb | <2000 ppb | <2000 ppb |

| Free chlorine | <3 ppm | <3 ppm | <3 ppm | <3 ppm |

| PH | 4-10 | 4-10 | 4-10 | 4-10 |

| Dissolved CO2 | <30 ppm | <30 ppm | <30 ppm | <30 ppm |

| Power supply | 20/40 series: 100-240V,50/60Hz, 60 series: 200-240V,50/60Hz | |||

| Total Power | 20/40 series: 120W, 60 series: 240W | |||

| Dimension (L×W×H) | Main host: 370×623×600mm | Main host: 370×623×600mm | Main host: 370×623×600mm | Main host: 370×623×600mm |

| Weight | Main host: about 28KG | Main host: about 28KG | Main host: about 28KG | Main host: about 28KG |

| Standard configuration |

Main host 1 set All cartridges 1 set 1.8-liter pressure water tank 1 set |

Main host 1 set All cartridges 1 set 1.8-liter pressure water tank 1 set |

Main host 1 set All cartridges 1 set 1.8-liter pressure water tank 1 set |

Main host 1 set All cartridges 1 set 1.8-liter pressure water tank 1 set |

| [1].Affected by inlet water quality, pressure, temperature and status of RO membrane | [2].Affected by the tank status and terminal filter | |||

| [3].The following values are typical and may vary depending on the nature and concentration of feed water contaminants | [4]. According to USP requirements, the resistivity can be displayed as a non-temperature-compensated value | |||

| [5].Affected by the type of organics | [6].Inlet TOC<1000ppb, follow professional operating procedures and correct sampling conditions | |||

| [7].Inlet TOC<50ppb, follow professional operating procedures and correct sampling conditions | [8].Equip with terminal microfilter and follow professional operating procedures and correct sampling conditions | |||

| [9].Equip with terminal microfilter and follow professional operating procedures and correct sampling conditions | [10].Equip with terminal microfilter and follow professional operating procedures and correct sampling conditions | |||